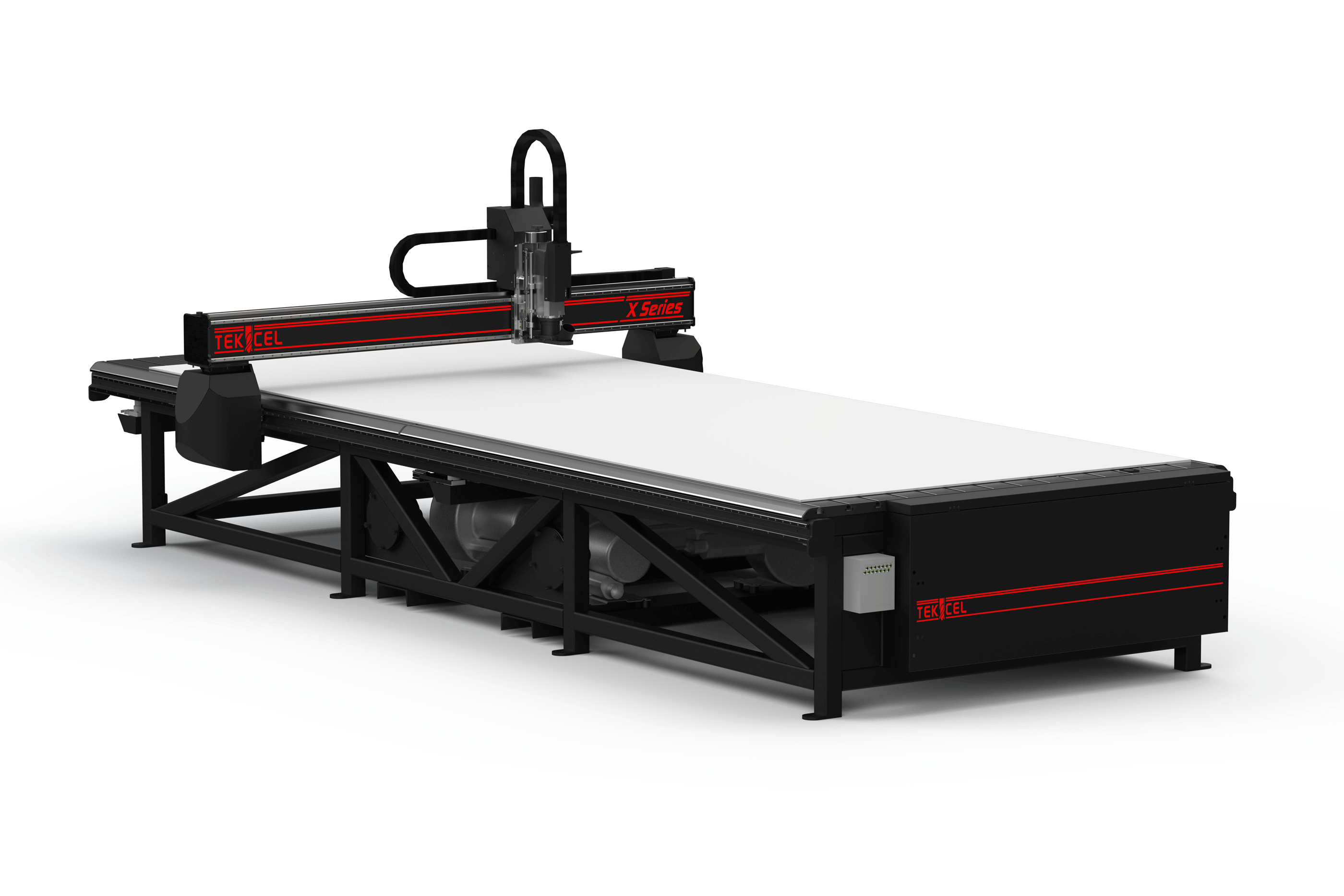

Process oversized sheets with ease on our large format CNC router.

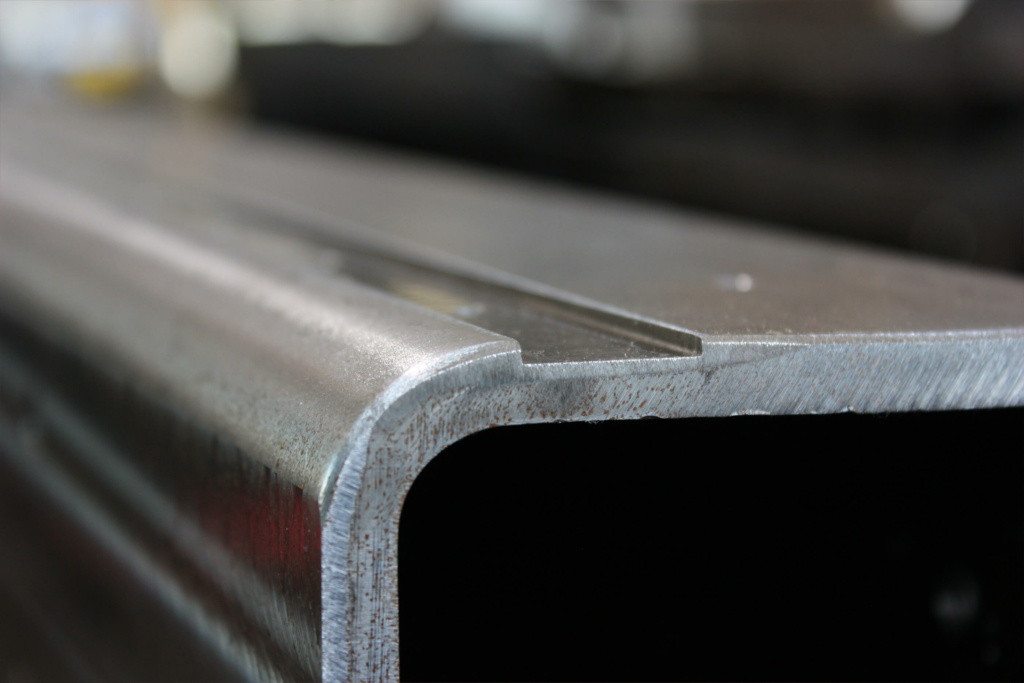

Our X Series offers our largest machine bed – capable of processing oversized sheets with ease. Designed specifically for marine manufacturing, this system can be configured with coolant and knife accessories for processing materials from solid aluminium sheets and extrusions, to SeaDek PE/EVA foam and marine carpet.

Industry Applications:

- Boat Building

- Aluminium Fabrication

- Plastic Fabrication

- Acoustic Panelling

Videos:

Jump to:

Key Features

Control System

Mechanical Features

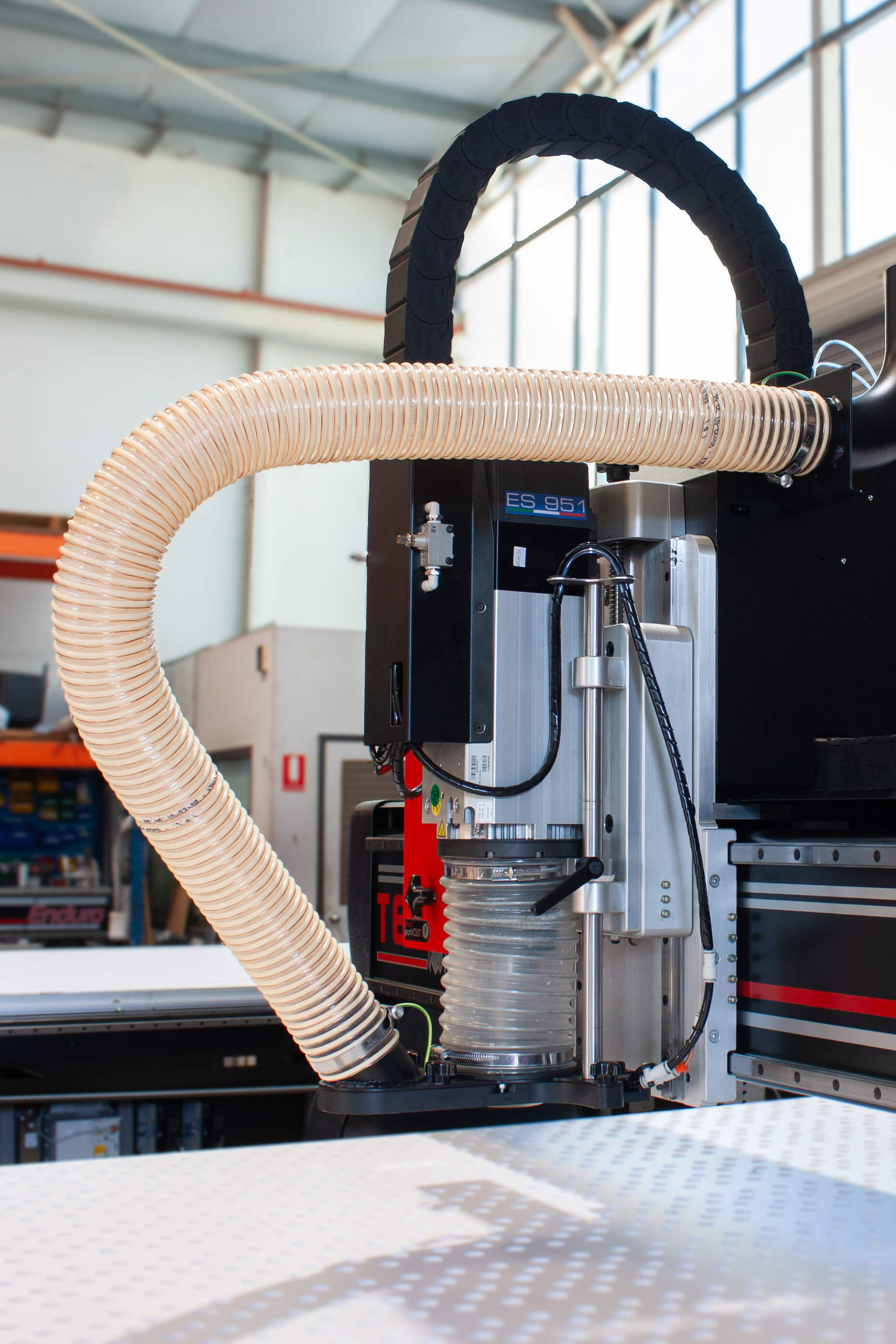

HSD Spindle (9kW)

Automatic Tool Change

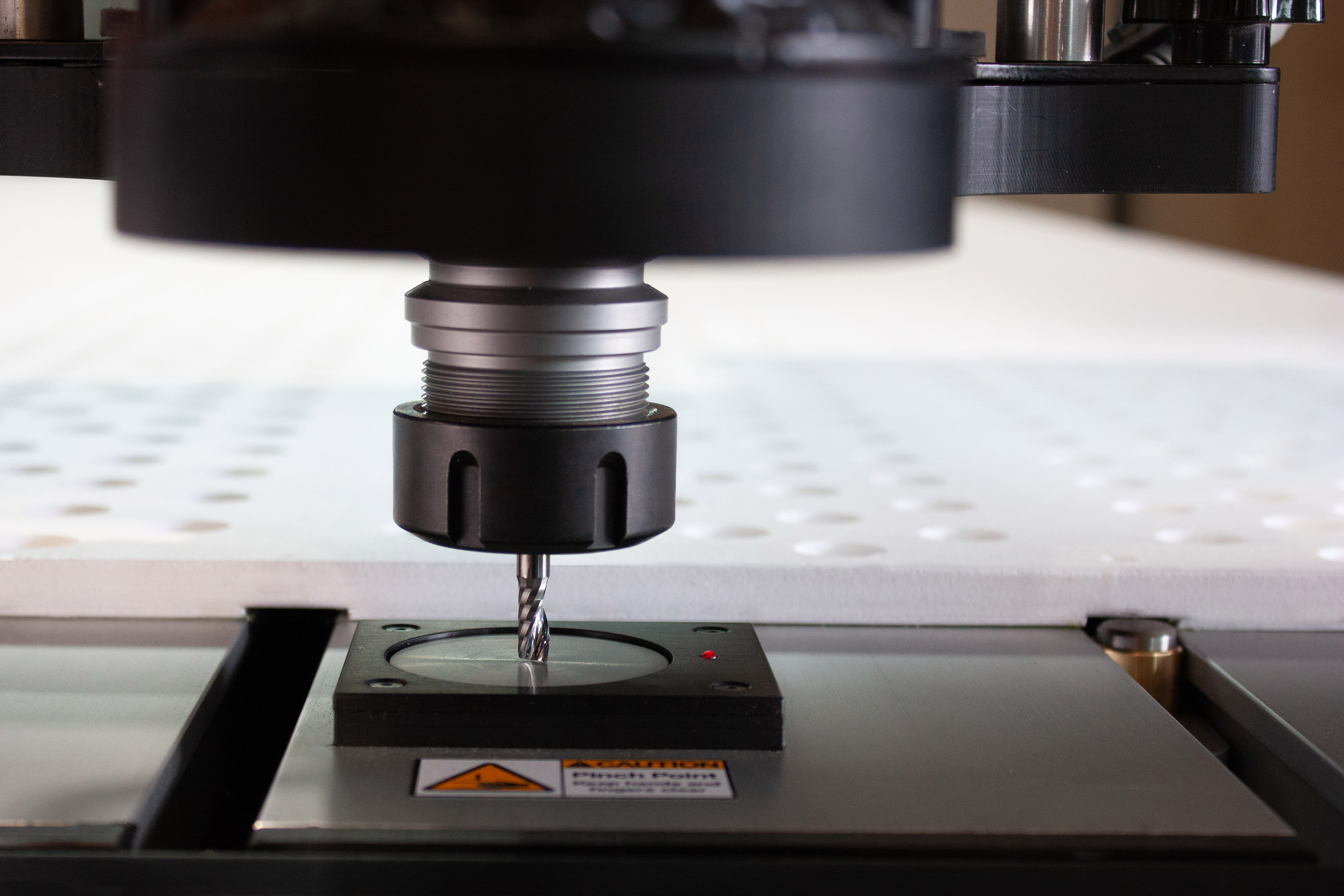

Automatic Tool Length Sensor

Rack & Pinion Drive

Linear Rails

Brushless Servo Motors

Table Top

Extruded Aluminium Slats

Alignment & Registration

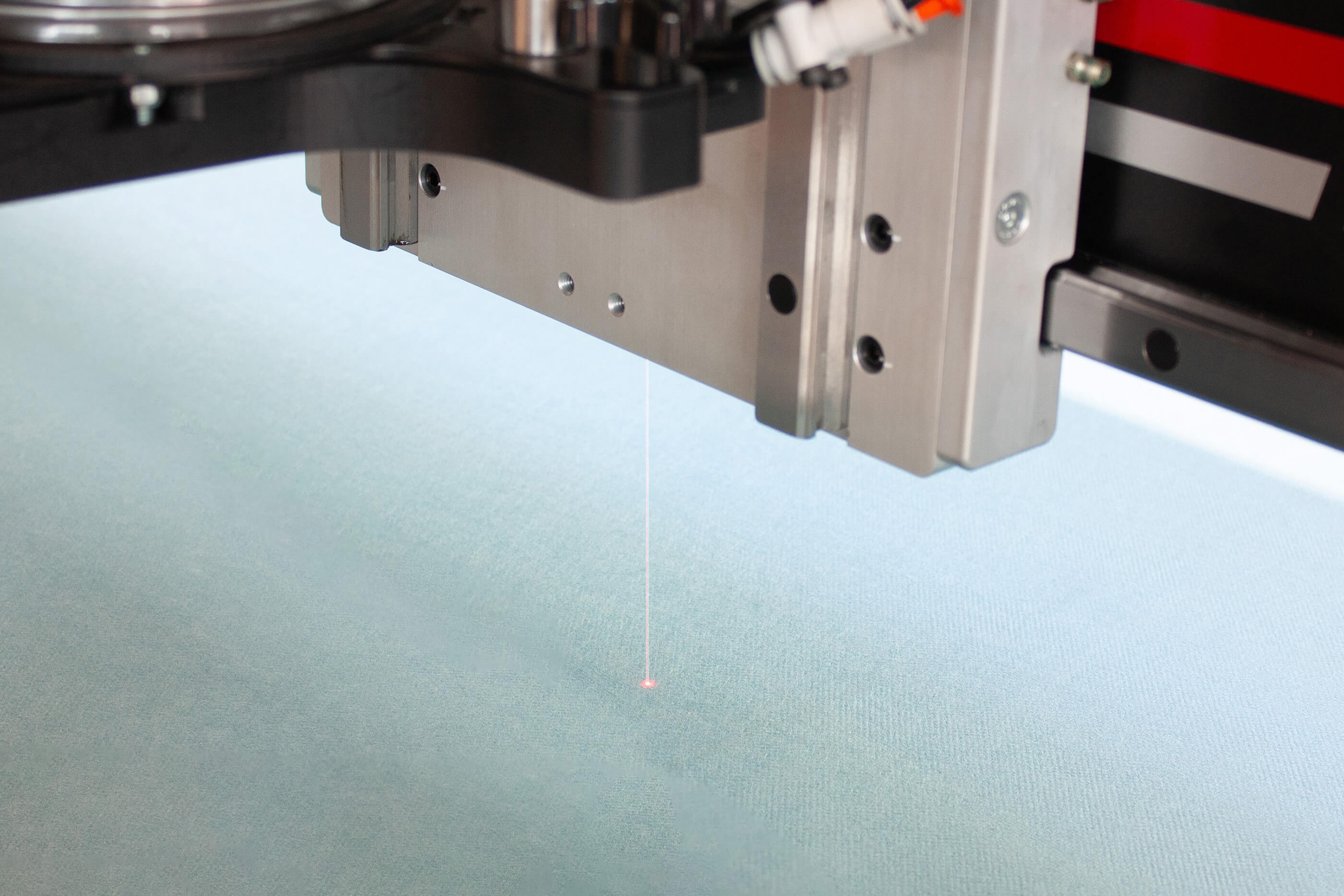

Laser Pointer

Dust Extraction

CAD/CAM Software

ProfileLab 2D Software

ProfileLab CAD/CAM software has been supplied with Tekcel routers for over 30 years. Training is included with each Tekcel machine, allowing you to create your own plot files, and personalize the tooling and materials library to streamline your workflow.

Specifically designed for CNC machining, ProfileLab 2D offers extensive 2D toolpathing capabilities without the extensive learning curve.

For more information, visit https://www.cadlink.com/product/profilelab-version-10-2d/.

Start Up Kits

Tooling Start-Up Kit

Our tooling startup kit ensures you have everything you need to get you up and running on delivery. Each machine comes with a set of three tool holders, your choice of three tools with matching collets, one skimming bit and a cover nut spanner.

Safety & Maintenance Kit

We provide a general safety and maintenance kit with every machine. This kit contains earmuffs, safety glasses, grease gun & coupler, grease cartridge, tool holder cleaning pad, CRC and shim plates for machine leveling.

Accessories

Alignment & Registration

Wireless Pulse Generator

Surface Probe

Our surface probe allows you to cut to a consistent depth on uneven surfaces. Great for unique materials or fine engraving work. The system creates a map specific to your material and references this continuously while cutting to ensure accurate depth at all points.

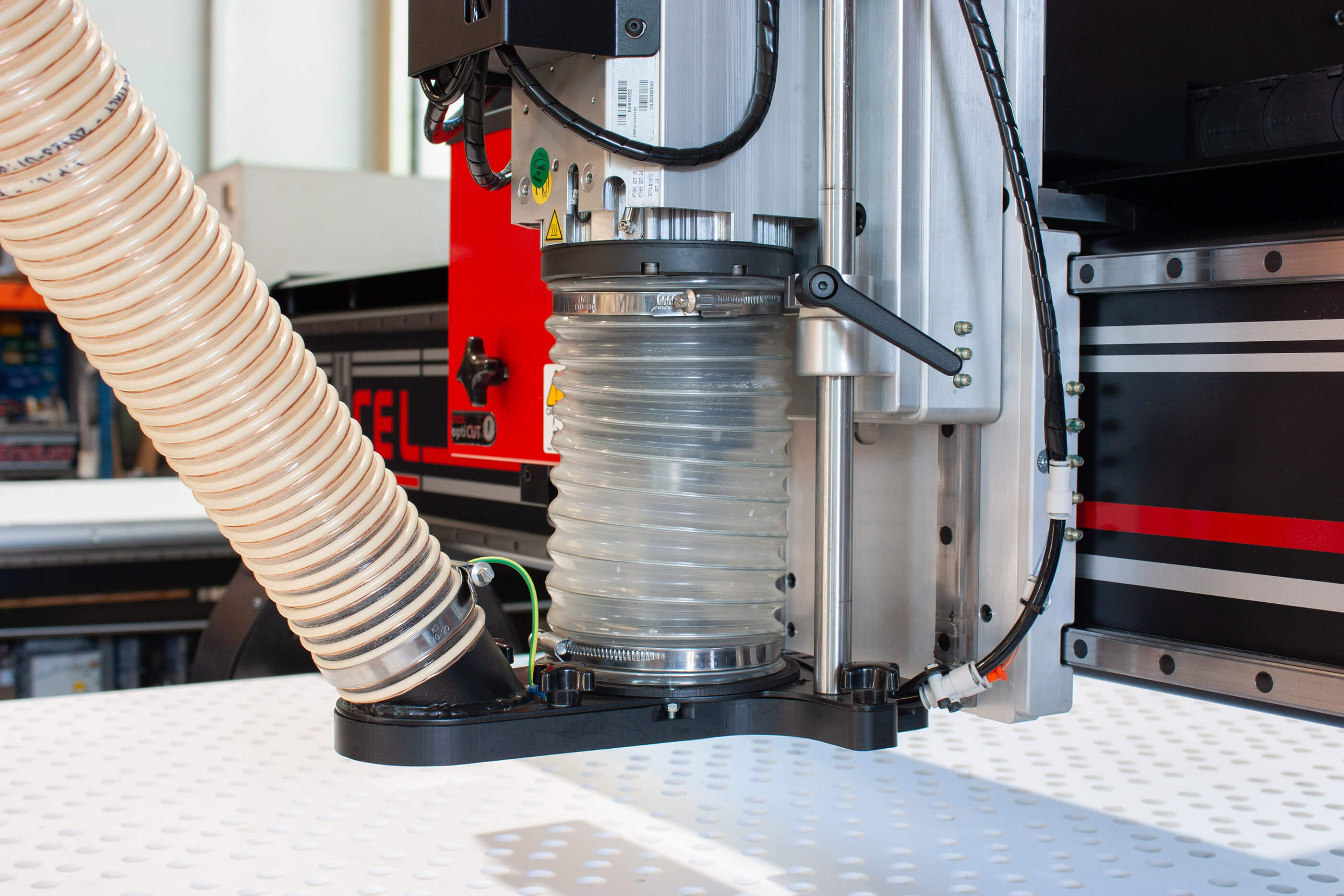

Dust Extraction

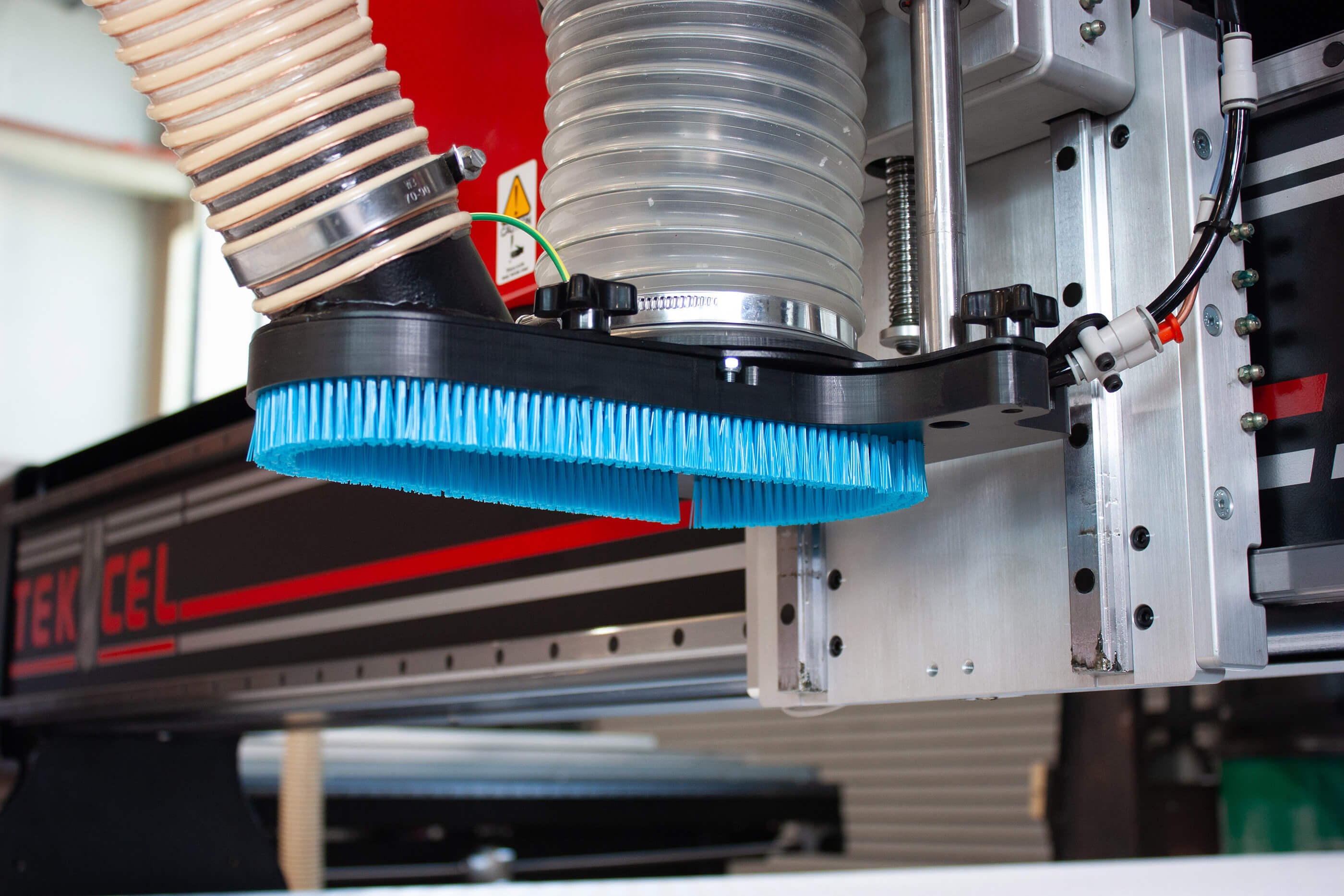

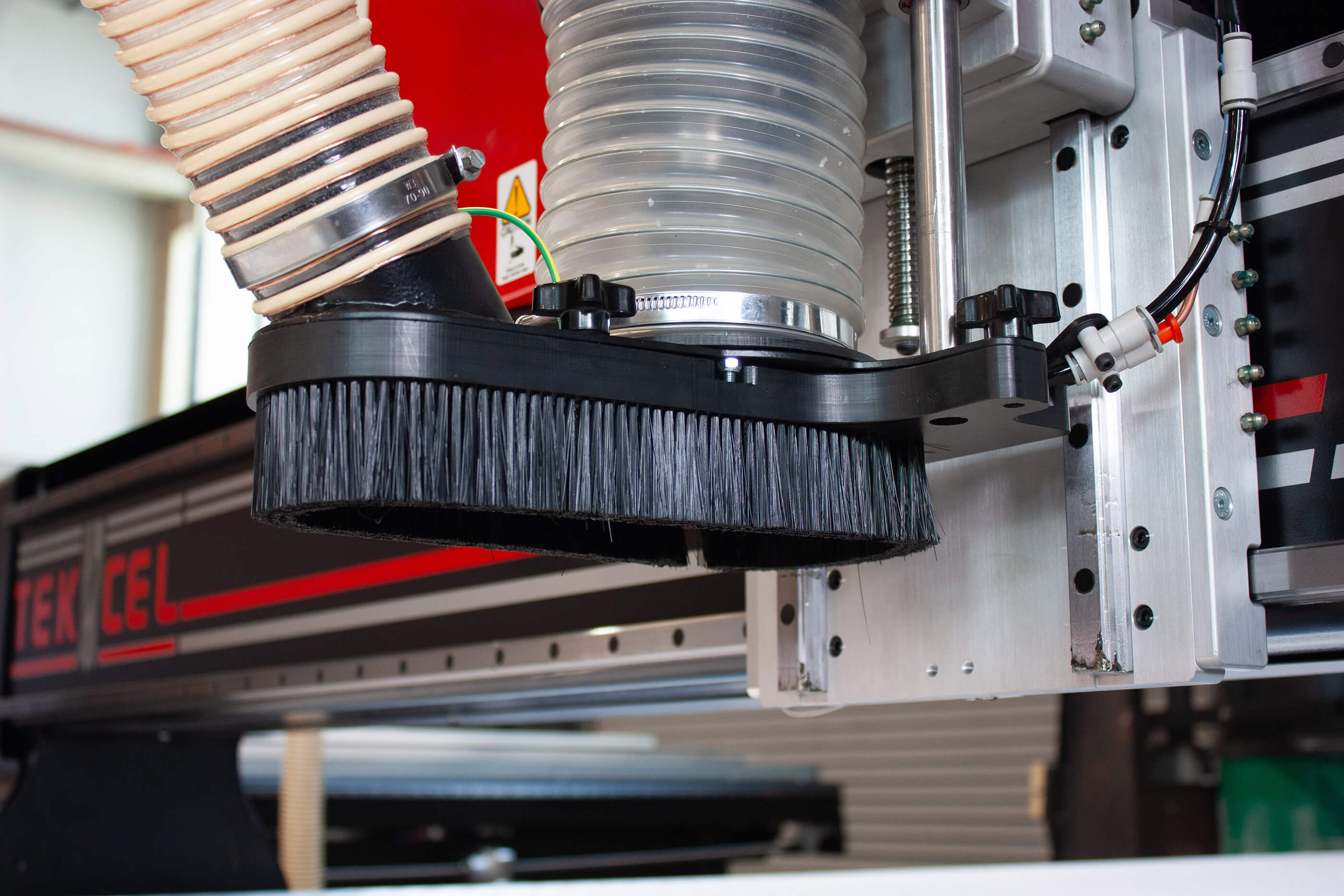

Bellows Short Bristle Attachment

Bellows Long Bristle Attachment

Tekcel Dust Extractor

Articulated Swing Arm

Dust Extractor Muffler

Vacuum Hold Down

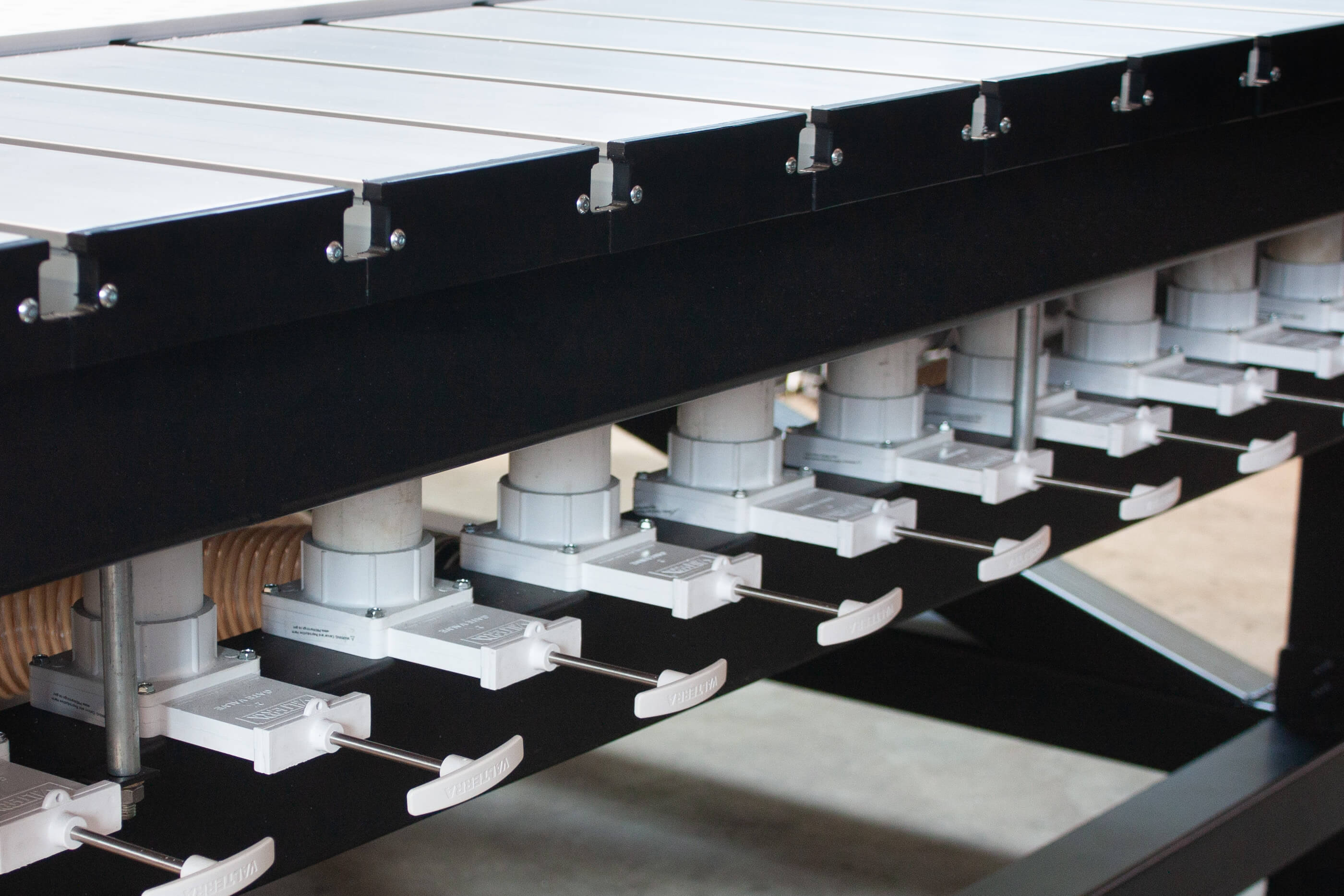

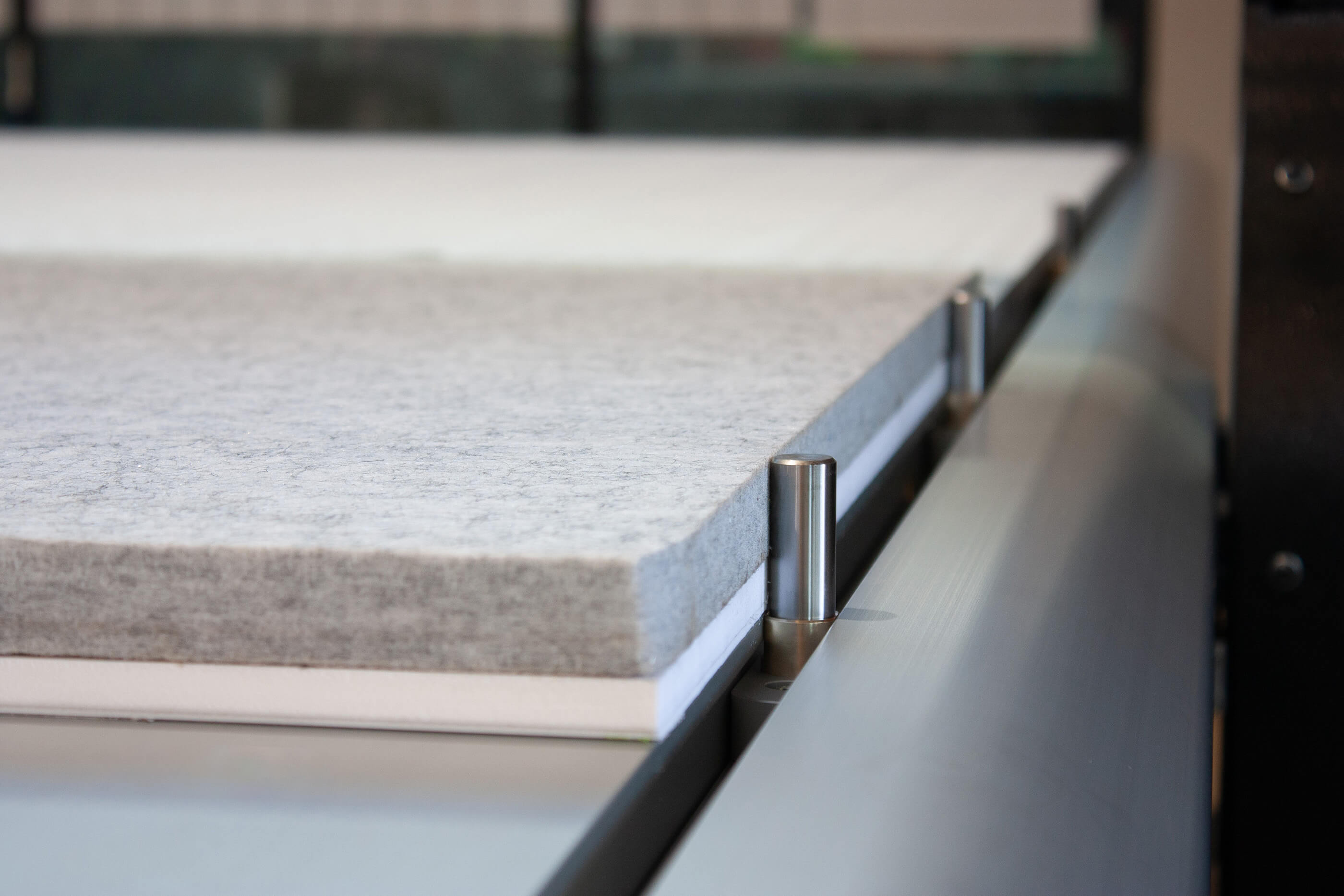

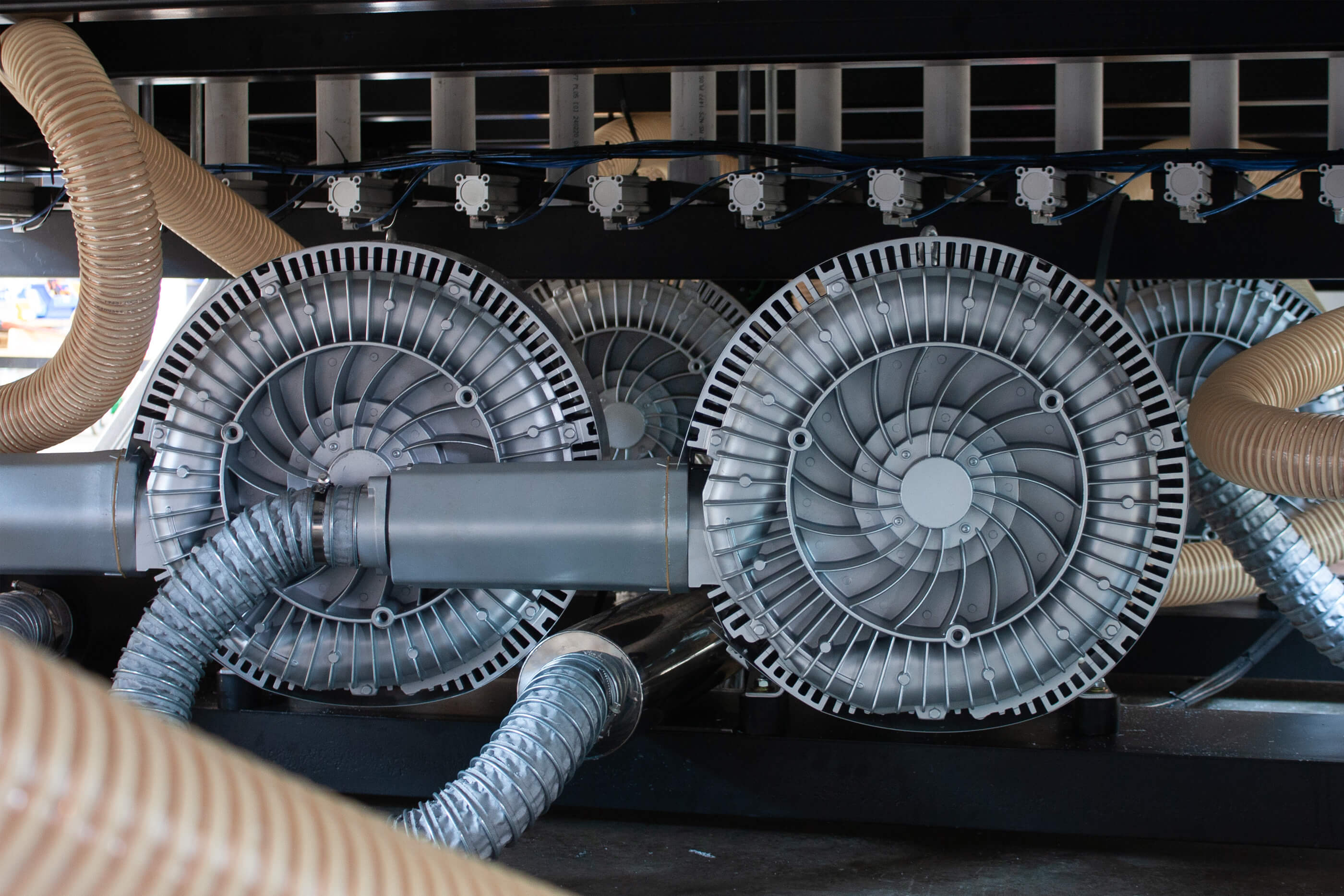

Matrix Vacuum Table Top

Our Matrix Vacuum Tabletop is divided into 28 zones. This highly configurable system is fit with four vacuum hold down pumps to effectively hold down a variety of sheet sizes. When needed, reverse the vacuum pumps to provide lift and reduce friction while sliding oversized sheets along the bed.

Two primary zones make up the vacuum tabletop; front and back. These zones can be further segmented into 14 sections – with each table slat acting as an independent vacuum channel.

Vacuum channels for the front of the machine are opened and closed pneumatically, with control buttons located at the front of the machine. The rear vacuum channels are controlled through manual valves located at the back of the machine.

Knife Cutting & Creasing

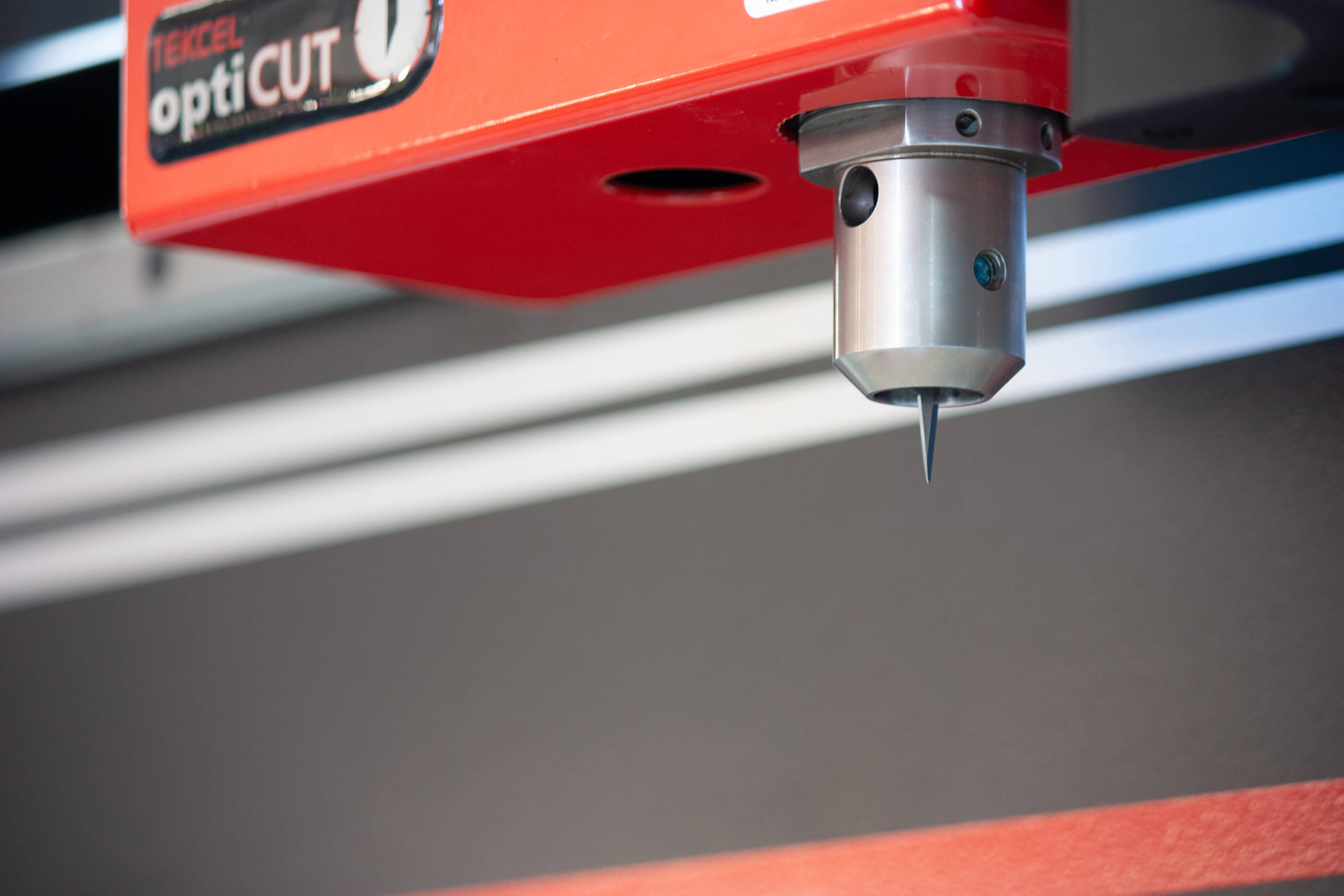

C Axis Knife

Suited to large scale knife work, where speed is priority. By developing our own aggregates, our C Axis Drive integrates a collection of knives into our existing auto tool change system. Minimizing operator intervention, and saving you time when processing multi-tool knife work.

Aggregate Options: Straight Drag Knife, 45° Drag Knife, Creasing Wheel, Cutting Wheel, Oscillating Knife, Light Weight Knife.

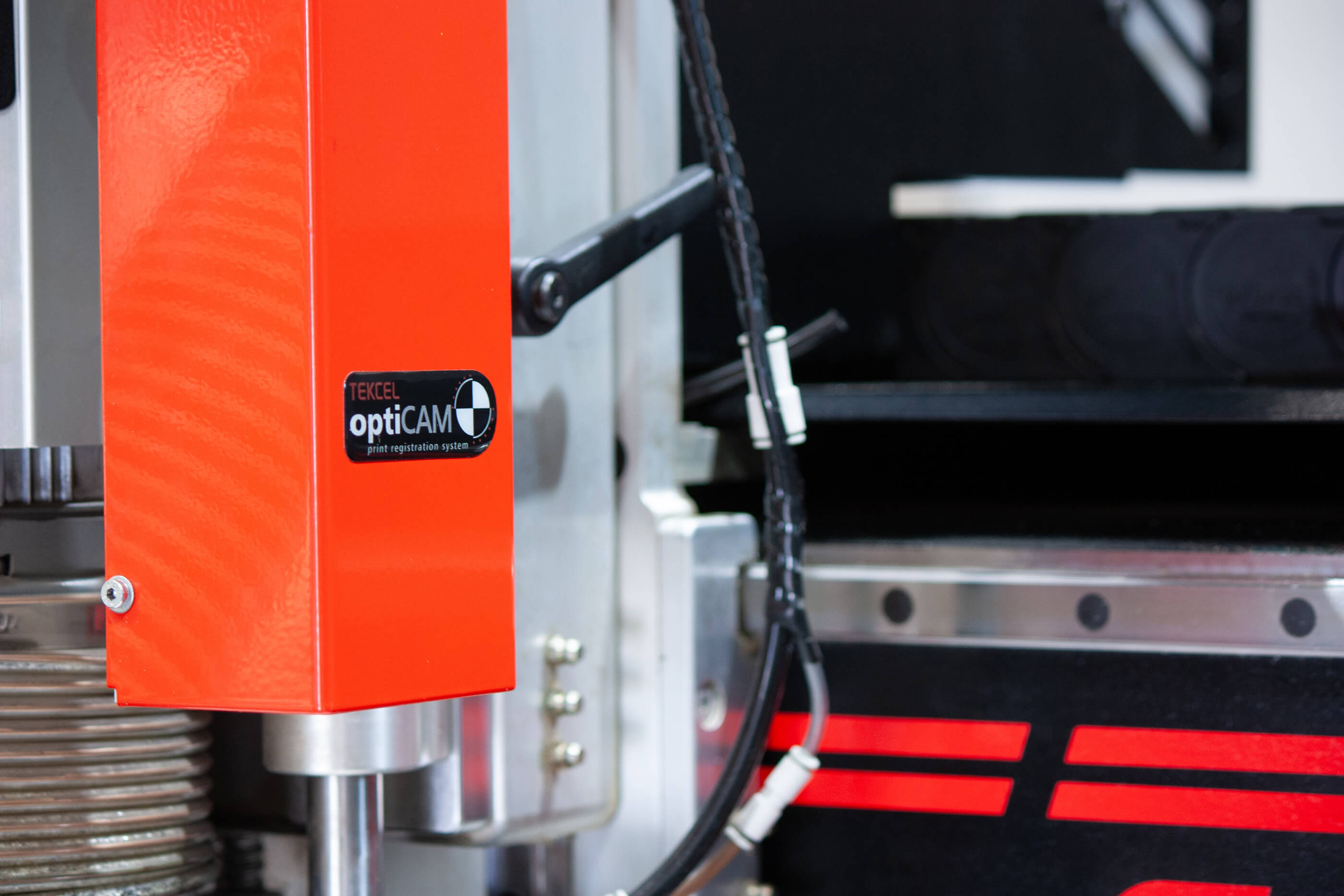

OptiCUT System

Camera & Registration

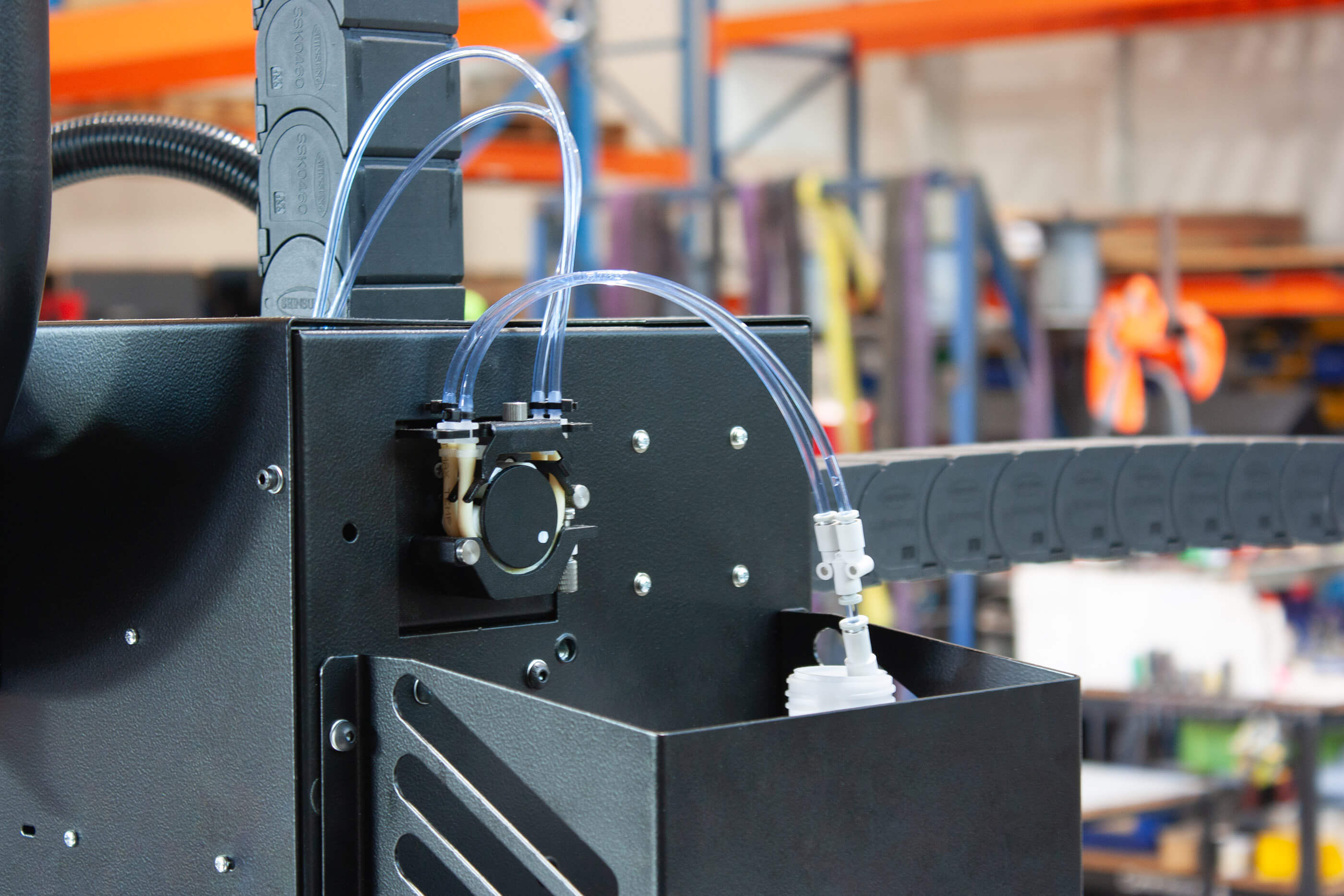

Coolant Systems

Safety Barriers

Light Curtain

Our light curtain keeps one machine side open, while still providing protection during machine operation. Using a parallel transmitter and receiver, an invisible safety screen is powered up while cutting. If obstructed, the machine stops – protecting the operator from moving machinery.

Light Curtain Corner

For use when two open machine sides are preferred. Use alongside our standard Light Curtain to reflect the light screen to 90 degrees. Wrap the screen around the side of the machine without compromising the integrity of the system.

Mesh Barrier

Mesh Barriers are used where the machine requires physical blocking. Barriers are made from 25mm x 25mm wire mesh. Height and width will be configured to your selected machine size and workshop requirements.

Size Options

| X Series | Router Processing Area (mm) | Footprint (mm) |

| 6200 x 2400 | X = 6200 • Y = 2400 | 7060 x 3020 |

Gantry Options

| Gantry | Max Material Thickness | Z Clearance |

| 140mm | 140mm | 155mm |

Note: Z clearance indicates distance between machine bed and bottom of the gantry. This number will decrease depending on the thickness of sacrificial sheet used. Please refer to maximum material thickness for processing capabilities.

Workshop Requirements

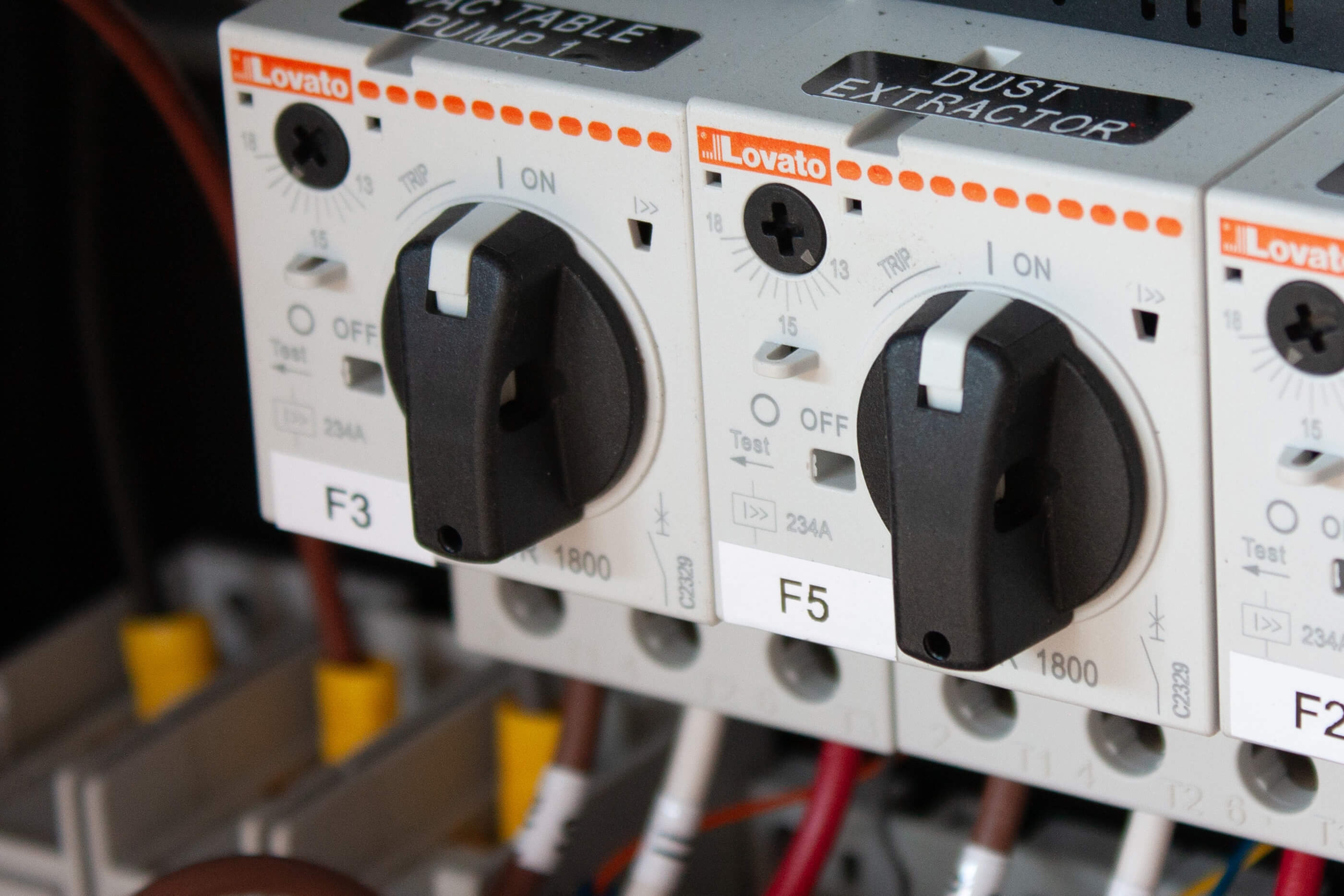

Power Requirements:

3-phase power with neutral & earth

Air Requirements:

Dry compressed air supply

Warranty

Tommotek offers a full 12 month warranty for their Tekcel CNC Routers from date of installation. This covers all parts of the machine from defects in materials and/or workmanship.

Note: This warranty may be void if the machine has been subject to accident, alteration, abuse or misuse, or unauthorized repair.

Request a Quote

Leave your details and we’ll be in touch to discuss the right machine for you.